Cold plunge pump troubleshooting is one of the most common concerns for ice bath users when water circulation or cooling performance suddenly drops.

When your cold plunge chiller pump stops working or your tub simply isn’t cooling as it should, it can disrupt your recovery routine and cause unnecessary frustration. This guide will walk you through the main causes, repair methods, and preventive measures for pump-related issues in cold plunge systems.

How the Cold Plunge Pump Works

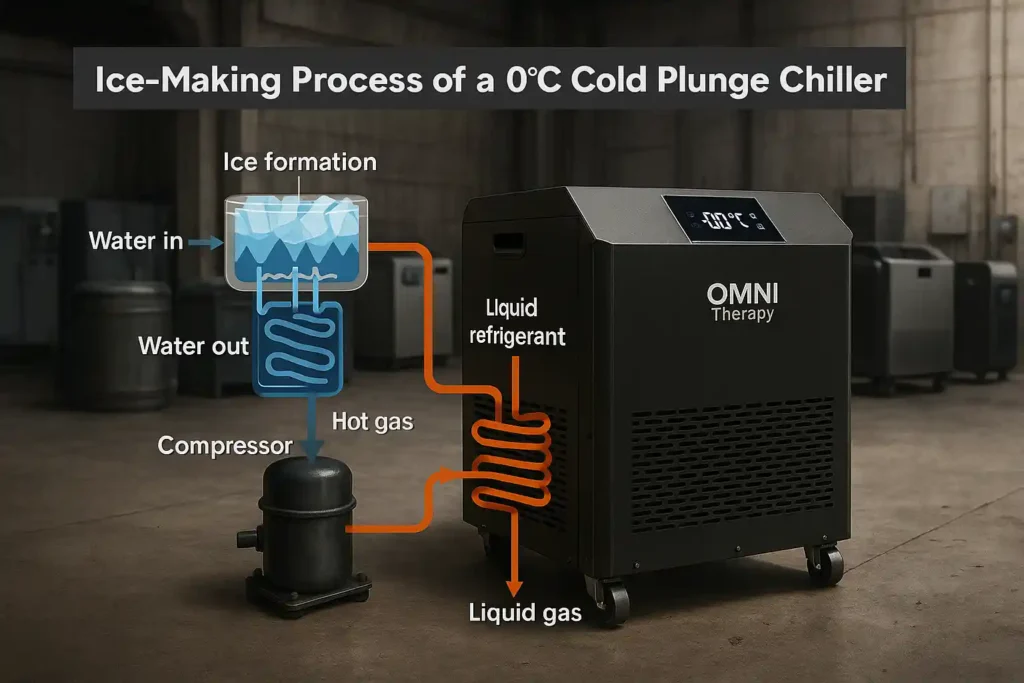

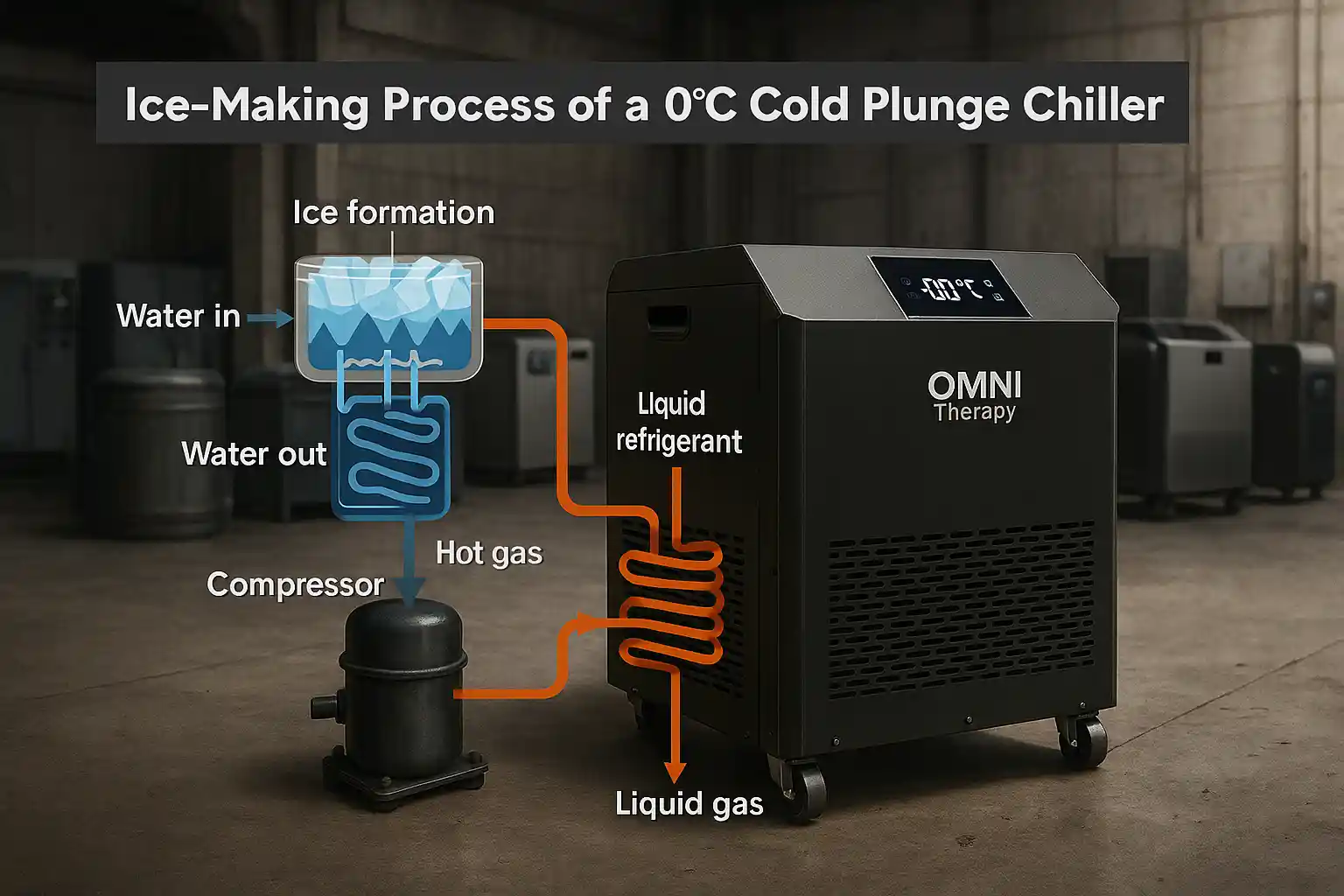

The chiller pump for cold plunge is responsible for circulating cold water from your tub through the chiller unit and back into the tub. This process ensures a consistent temperature and even cooling. If the pump fails, you might experience:

Water not moving at all (cold plunge pump not working).

Water circulating but not cooling (plunge not cooling).

Inconsistent flow or strange noises.

Why Pump Performance Affects the Entire Chiller System

The pump does more than move water—it determines how efficiently the chiller can extract heat from the system.

When flow rate drops, cold water does not circulate evenly, causing temperature fluctuations and increased strain on the chiller unit.

Over time, this imbalance can lead to system-wide issues that require full cold plunge chiller troubleshooting rather than simple pump repair.

Common Pump-Related Issues

Below are the most frequent pump-related problems in cold plunge setups:

No Water Flow

Blocked filter or debris inside the pump.

Loose hose connections.

Electrical connection failure.

Pump Runs but No Cooling

The chiller is on but the refrigerant cycle is interrupted (cold plunge chiller repair may be required).

Water temperature sensor malfunction.

Low Flow Rate

Impeller damage.

Mineral buildup in the pipes.

Kinked or bent hoses.

While pump-related issues are one of the most common cold plunge failures, they are usually part of a larger system problem.

For a complete, system-level diagnosis—including filters, chillers, circulation, and temperature control—see our full Cold Plunge Chiller Troubleshooting & Maintenance Guide.

Step-by-Step Troubleshooting

If your cold plunge pump not working, follow these steps:

Step 1: Check Power & Controls

Ensure the unit is plugged in.

Confirm your smart control or manual switch is on.

Step 2: Inspect the Filter

Remove and clean the filter to restore flow.

For units with integrated filtration (cold plunge pump and chiller systems), check both the primary filter and pre-filter.

Step 3: Flush the Lines

Disconnect hoses and flush with clean water to remove any blockage.

Step 4: Test the Pump

If the pump still won’t run, test it with a separate power source to confirm if the motor has failed.

If pump operation appears normal but cooling performance is inconsistent, the issue may extend beyond the pump itself.

In these cases, a full cold plunge chiller troubleshooting process is recommended to inspect filters, heat exchangers, and circulation efficiency.

Preventive Maintenance

Weekly: Rinse the filter and check for debris.

Monthly: Inspect hose connections and fittings.

Quarterly: Perform a deep clean and descale the system.

Routine maintenance can extend pump life significantly and prevent emergency cold plunge chiller repair needs.

Common Mistakes That Lead to Pump Failure

Many pump issues are caused by setup and usage errors rather than defective parts.

Running the pump without proper filtration, allowing air to enter the hoses, or operating the system with low water levels all increase wear on the motor.

Avoiding these mistakes significantly reduces the need for emergency cold plunge pump troubleshooting.

When to Replace the Pump

If your cold plunge pumps show signs of motor burn, excessive vibration, or persistent failure even after repair, replacement may be more cost-effective than continued maintenance

Choosing a Replacement Pump

When selecting a new pump for your cold plunge, consider:

Flow Rate (L/min) that matches your chiller.

Power Compatibility with your electrical setup.

Material Quality for corrosion resistance.

If your tub is larger or used commercially, pairing with a high-performance Ice Bath Chiller Manufacturer model can maximize cooling efficiency.

Recommended Chiller Systems

For pumps paired with chillers, we recommend:

CHU Series for 0°C capability.

CHM Series for smart control.

CH-08 for budget-friendly home use.

Learn more in our Cold Plunge Chiller Manufacturer Asia – Top Factory for Global Buyers page.

External Resources

Pump failures are often the first visible symptom of a deeper system issue.

If troubleshooting the pump does not fully resolve your problem, follow our complete cold plunge chiller troubleshooting guide to ensure every component is inspected and maintained properly.

For a deeper technical understanding of pump mechanics, you can review Pumps and Circulation Systems Guide – Engineering Toolbox.