A cold plunge chiller and filter isn’t just a nice upgrade—it’s the difference between a novelty tub and an auditable, low-downtime recovery asset. In facilities where dozens of people cycle through daily, the winning installs do three things well: hit dose-controlled temperatures every time, keep water hygiene verifiable, and pass operational scrutiny (logs, standards, and safety). Public health guidance (MAHC) and product standards (NSF/ANSI 50) now make it practical to engineer small plunge systems with the same discipline as larger aquatic venues To understand how modern cold plunge systems integrate cooling, filtration, and hygiene into a single, reliable recovery solution, see our cold plunge chiller with filter complete guide.

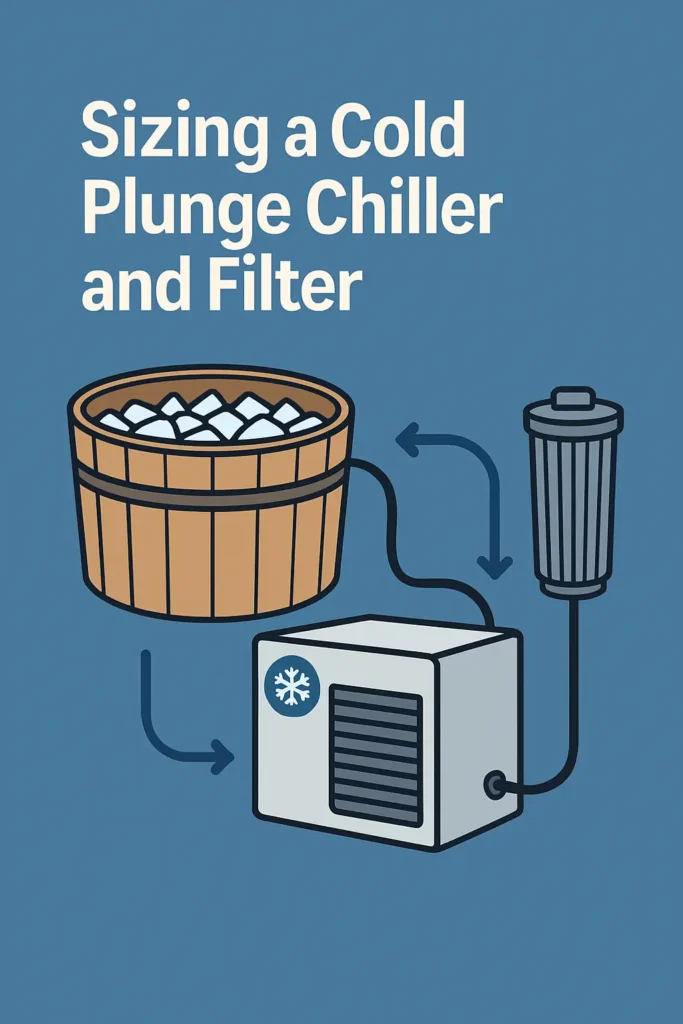

What exactly is a “chiller + filter” loop—and why order matters

A reliable loop looks like this:

Tub → pre-filter (cartridge or sand) → circulation pump → chiller heat-exchanger → return to tub.

Putting the filter before the chiller shields the heat-exchanger from grit and organic load, protecting cooling efficiency and extending seal/pump life. In higher-traffic environments, add UV or ozone as secondary disinfection. When components align with NSF/ANSI 50 (filters, pumps, UV, controllers, feeders), you’re working inside a well-understood performance envelope referenced by many health codes. nsf.orgThe ANSI Blog

For a ready-matched kit approach, compare models under Cold Plunge Systems – Tubs,Chillers & Full OEM Combos and shortlist by volume, turnover, and serviceability.

This loop logic—especially filter-first protection and turnover control—is explained in more detail in our complete guide to cold plunge chillers with filters, including sizing, hygiene standards, and real-world maintenance considerations.

Dose the cold, not just the hype: evidence-based temperature × time

Across recent reviews and meta-analyses, cold-water immersion (CWI) after exercise meaningfully reduces DOMS and perceived fatigue versus passive recovery. The most practical and repeatedly supported “dose band” is ~11–15 °C for ~10–15 minutes for soreness reduction; colder (5–10 °C) can shift biochemical markers but tends to be less tolerable day-to-day for teams. Program exposure around your training goals and avoid immediate CWI after hypertrophy-focused sessions if maximizing muscle growth is the priority

Hygiene & compliance: what inspectors (and good operators) expect

The Model Aquatic Health Code (MAHC) provides the logic behind turnover, disinfection, and records—principles that scale down to small plunge vessels when you want predictable water quality:

Turnover: engineer flow so the vessel water is recirculated on a predictable schedule.

Verified filtration: select filters with proven performance and size them to bather load and volume.

Residuals & pH: keep measurable disinfectant residuals within pH ranges and log them.

Documentation: keep filter maintenance, temperature, and chemistry logs—this is what resolves incidents fast.

The Annex to MAHC details scientific rationale and helps you justify choices to stakeholders or authorities.

Need component signals of quality? NSF/ANSI 50 is the common reference for filters, pumps, UV, controllers, etc.; using certified components speeds procurement and supports inspections

Engineer the loop: sizing that actually works

4.1 Turnover (circulation)

Target 2–4 turnovers/hour for shared use.

Example: a 400 L tub at 3 turnovers/hour → 1,200 L/h (~20 L/min) delivered after head loss through hoses, filter, and chiller. Use the pump curve, not just the nameplate.

4.2 Filtration

Cartridge filters: straightforward service; for clarity and heat-exchanger protection choose ~5–20 µm elements; replace per differential pressure.

Sand filters: robust for higher loads; backwash per spec when pressure rises.

Secondary disinfection: UV or ozone reduces combined organics and smell in busy facilities—again, look for NSF/ANSI 50 alignment. nsf.org

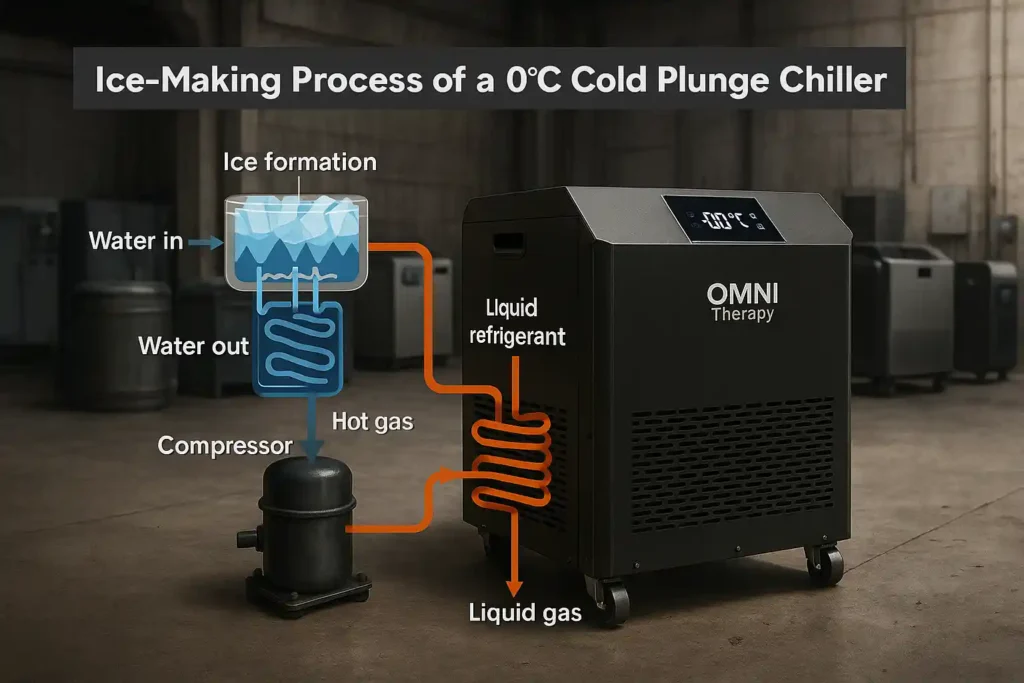

4.3 Chiller capacity & controls

Size HP to your volume and schedule so you consistently hit 11–15 °C inside the operational window without short-cycling.

Controls: stable PID temperature control, flow/level alarms, anti-freeze/anti-dry-run protections.

Power: 110/220 V to match site; ensure GFCI/RCD compliance.

Placement: give the condenser adequate ventilation; heat-dumping in confined closets ruins performance.

TCO/ROI: the filtered chiller wins on cash and uptime

Assumptions (customize to your site): 400 L tub; drop 20 → 12 °C; one session/day.

Ice method (latent heat): you melt about 40 kg of ice for the 8 °C drop; real use (door opens, human load, ambient heat) pushes daily ice closer to ~60 kg. At $0.30/kg, that’s $18/day ≈ $540/month ≈ $6,480/year.

Chiller + filter: ~0.9 kW compressor × ~6 h/day ≈ 5.4 kWh/day. At $0.15/kWh, $0.81/day ≈ $292/year electricity. Filters/consumables ≈ $260/year.

Annual delta: ~$6,000 saved. With a $1,200–$2,000 system, payback is typically 2–4 months, then you bank OPEX every month thereafter.

Money aside, filtration preserves clarity, reduces complaints, and protects pumps/heat-exchangers—exactly what MAHC-style operational logic is meant to achieve

Implementation blueprint: from survey to SOP

Step 1 — Site survey

Measure vessel volume; map an equipment pad with drainage; confirm power, ventilation, and hose runs.

Step 2 — Loop design

Pick cartridge vs. sand; size pump for target turnover; confirm hose diameters/quick-disconnects; add check valves where needed.

Step 3 — Controls & safety

Set PID control with lockouts; verify flow/level sensors; GFCI/RCD; anti-freeze; audible alarms.

Step 4 — Commissioning

Leak test; verify flow in LPM and ΔT; record time-to-target temperature; set filter change thresholds by differential pressure.

Step 5 — SOP + logs

Daily: temperature, disinfectant residual, pH. Weekly: rinse/ backwash; check hoses/unions. Monthly: replace cartridges (or earlier if ΔP threshold is hit). Keep a single-page incident response for cloudy water/odor.

Want a factory-grade starting point? Compare OEM-matched kits under Cold Plunge Systems – Tubs, Chillers & Full OEM Combos, then step up to a fully custom loop via our ice bath chiller manufacturer hub.

Five common failure modes (and how the filter prevents them)

Filter placed after the chiller → debris fouls the heat-exchanger first; efficiency tanks.

Undersized filter area → high ΔP, cavitation, seal wear, and nuisance shutdowns.

Ignoring head loss → delivered flow misses turnover target; chemistry “dead zones.”

No secondary disinfection at high load → cloudy water and odor despite decent filtration.

No records → you can’t diagnose trends or pass audits; MAHC-style logs fix this.

Buyer’s checklist (copy into your RFQ)

Chiller: capacity vs. volume; time-to-target; ±0.5 °C stability; noise; power; alarms; placement ventilation.

Filter: micron rating; effective area; pressure gauges; service method (backwash vs. replace); spare parts availability.

Turnover: guaranteed delivered flow at your plumbing layout; pump curve + head-loss calc.

Compliance: components meeting NSF/ANSI 50 or local equivalent; chemistry guidance. nsf.org

Docs: installation manual, SOP, consumables list, service video links.

For hands-on assembly steps, see your in-house guide Cold Plunge Chiller and Filter Setup – Complete System Guide (use this article’s full title as the anchor when linking internally).

Programming the cold: practical “dose templates”

Team recovery days: 10–15 min @ 0–5 °C, within 30–60 min post-session (DOMS focus).

Back-to-back schedules: shorter, tolerable exposures (5–8 min) to aid adherence while maintaining hygiene/uptime.

Strength blocks: avoid immediate CWI post-hypertrophy if the prime goal is muscle growth; move CWI to conditioning days or later.

What to show an inspector (or your risk manager)

Component spec sheets noting NSF/ANSI 50 compliance (filters, pumps, UV, automated controllers) and electrical protections.

Daily chemistry and temperature logs, plus filter ΔP service records.

SOPs referencing MAHC logic on turnover and disinfection and the 2024 Annex rationale where useful.

Bottom line

When you treat a cold plunge chiller and filter like a miniature aquatic venue—sized for turnover, filtered for clarity, documented for safety—you get repeatable physiology (dose-controlled temperatures), reliable hygiene, and lower lifetime cost. That’s what keeps athletes coming back and downtime off the calendar.

When you treat a cold plunge chiller and filter like a miniature aquatic venue—sized for turnover, filtered for clarity, and documented for safety—you move from guesswork to repeatable performance.

If you want a complete, system-level explanation of how cooling capacity, filtration design, hygiene standards, and real-world operation fit together, read our Cold Plunge Chiller With Filter: The Complete Guide to Clean, Cold Recovery.