New Opportunities for Ice Bath Chillers in Vietnam

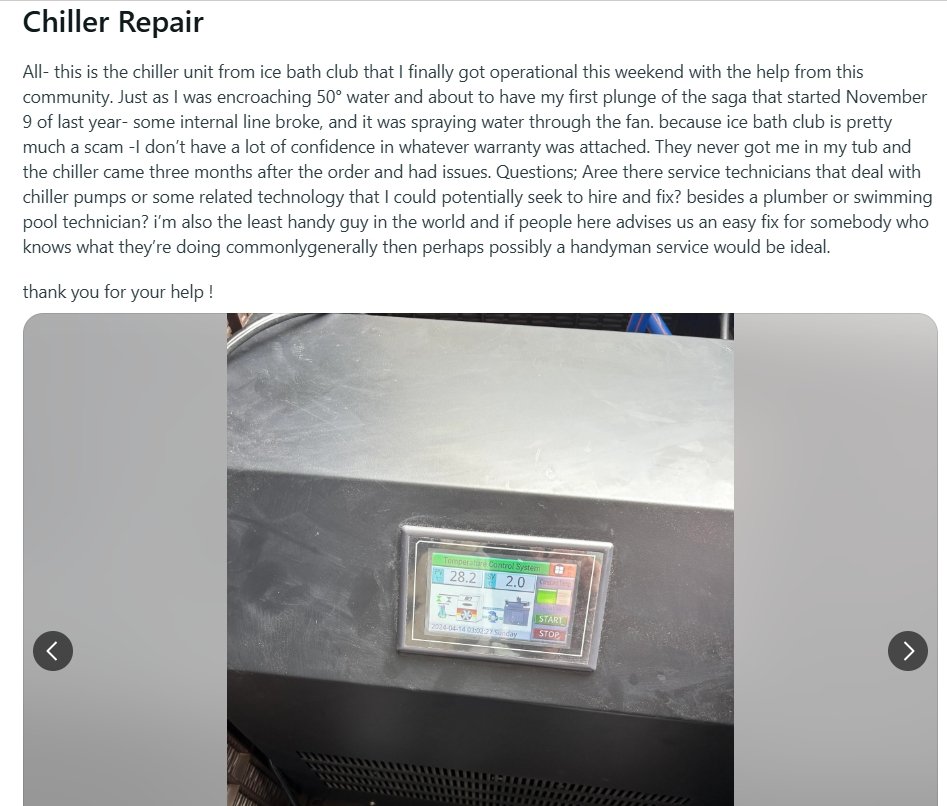

Why Ice Bath Chiller Buyers Are Shifting Away from China

Global buyers are increasingly searching for ice bath chillers Vietnam as a smarter alternative to Chinese-made units. The combination of lower tariffs, better product quality, and improved manufacturing infrastructure is making Vietnam a top destination for sourcing cold plunge chillers.

(CNBC Report on Chinese Manufacturing Issues).

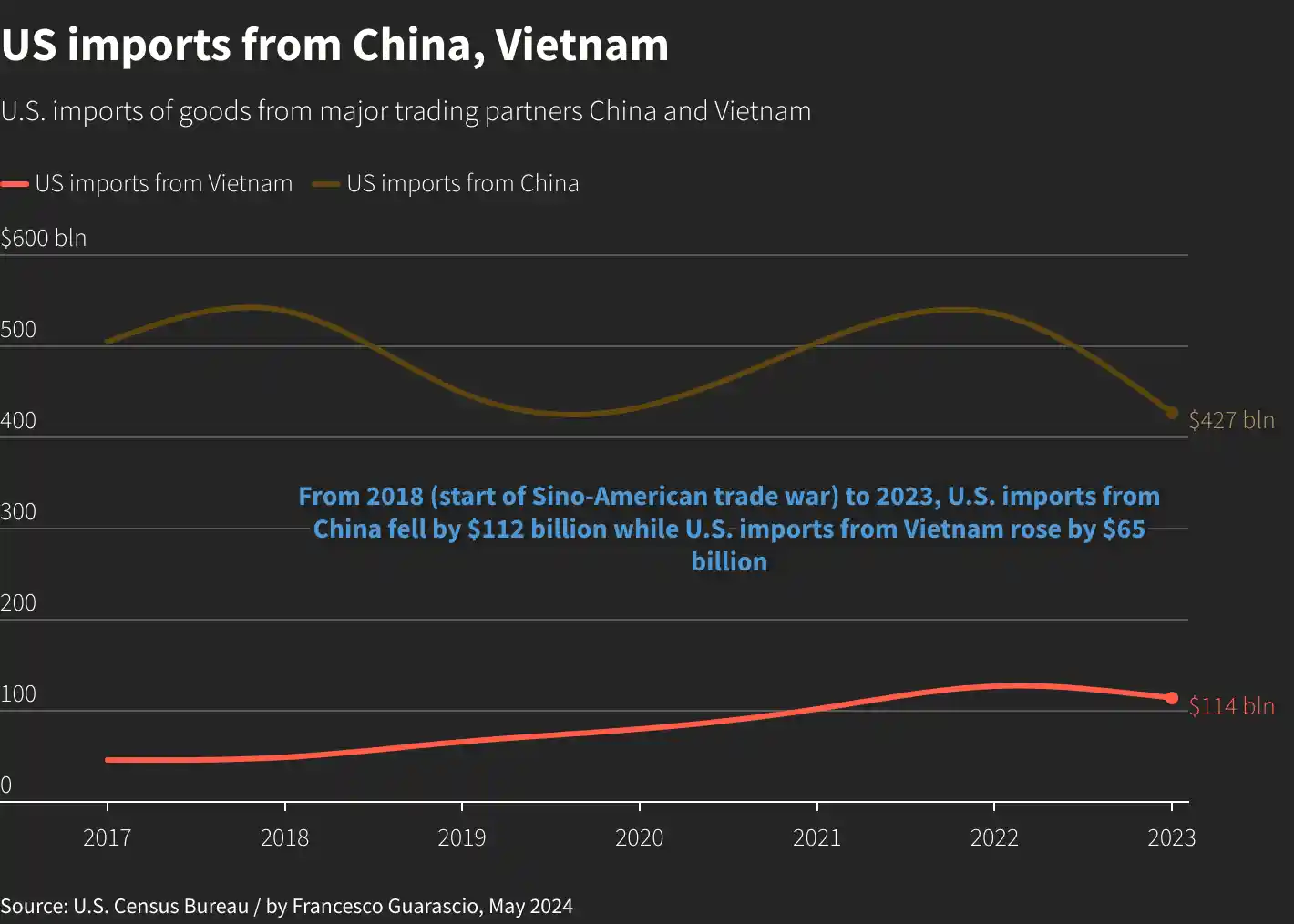

How U.S. Tariffs Impact Ice Bath Chiller Importers

One of the most pressing concerns for international buyers is the increasing cost burden from tariffs on Chinese products. The U.S. has imposed tariffs of up to 25% on chillers manufactured in China, dramatically inflating import costs (U.S. Customs Tariff Schedule). These additional costs directly affect profitability, competitiveness, and customer satisfaction. In contrast, chillers produced in Vietnam enjoy significantly lower tariff rates or even tariff-free entry, creating substantial cost savings for importers serving the U.S. market. Avoiding tariffs through Vietnamese manufacturing thus provides an immediate competitive edge.

Why Vietnam Leads in Ice Bath Chillers Vietnam Production

Vietnam has emerged as an optimal alternative for manufacturing ice bath chillers due to several strategic advantages:

Competitive Labor Costs: Vietnamese manufacturing labor costs are generally comparable with those in China, allowing for efficient cost management while maintaining high production quality (Vietnam Labor Costs Analysis).

Stable Business Environment: Vietnam offers a politically stable, investment-friendly environment, making it easier for manufacturers to establish and maintain high-quality production lines (World Bank Ease of Doing Business).

Rapidly Improving Infrastructure: Significant investments in logistics, ports, and transportation infrastructure mean that products manufactured in Vietnam can efficiently reach global markets (Vietnam Infrastructure Development).

Favorable Government Policies: Vietnam actively encourages foreign investment through attractive policies, including tax incentives, simplified business registration procedures, and strong protections for intellectual property rights (Vietnam Investment Policies).

Vietnam Chiller Manufacturer Certifications and Ice Bath Standards

Vietnamese manufacturing has increasingly aligned with international quality standards such as ISO 9001 and CE certification (ISO Certification). Factories in Vietnam are equipped with advanced machinery and employ skilled technicians trained in rigorous quality assurance processes. Extensive training programs and continuous professional development ensure manufacturing excellence. This commitment guarantees that ice bath chillers produced in Vietnam reliably meet or exceed international expectations, reducing the risks associated with equipment failure or operational interruptions.

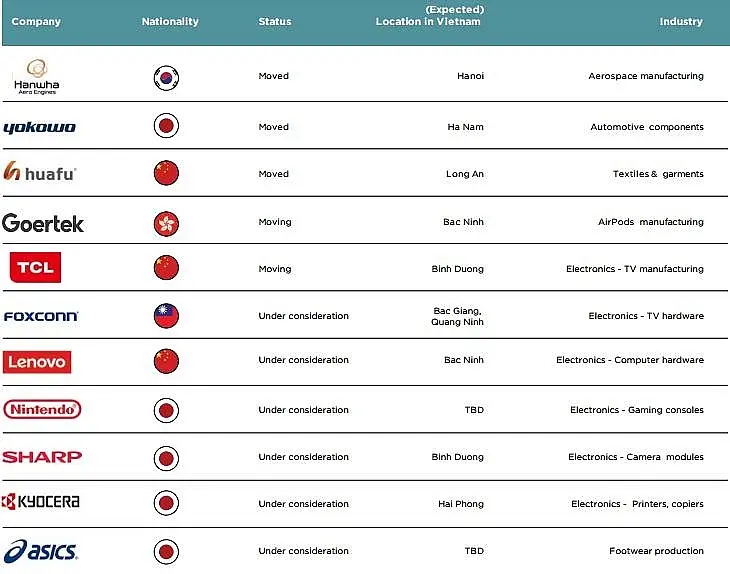

Why China’s Ice Bath Chiller Brands Are Relocating to Vietnam

Interestingly, many reputable Chinese manufacturers themselves are relocating their factories to Vietnam. This migration allows them to maintain high production standards, eliminate tariff disadvantages, and continue effectively serving customers in the U.S. and Europe (Reuters on Chinese Manufacturers in Vietnam). Buyers thus benefit from the proven technical expertise previously associated with China, now combined with the superior business advantages of Vietnam. This shift also signifies market validation of Vietnam’s capability to produce high-quality chillers, further boosting buyer confidence.

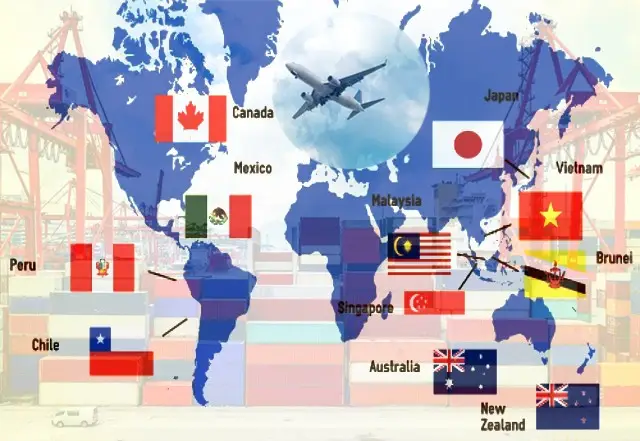

Vietnam’s Export Strength for Ice Bath Chillers

Vietnam’s strategic geographic location and extensive trade agreements with major global markets, including the U.S. and European Union, significantly enhance its export potential. Agreements such as the EU-Vietnam Free Trade Agreement (EVFTA) (EVFTA Details) and Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) (CPTPP Overview) reduce trade barriers, streamline export processes, and create substantial business opportunities for companies sourcing from Vietnam. Consequently, buyers benefit from quicker, more reliable, and cost-efficient product delivery.

How Our Vietnam-based Manufacturing Benefits You

By choosing ice bath chillers made in Vietnam, you gain:

Reduced costs due to favorable tariffs and efficient production expenses.

Improved quality and reliability, minimizing equipment downtime and maintenance.

Strategic business advantages, positioning your company ahead of competitors still sourcing from China.

Enhanced supply chain flexibility, allowing for faster responsiveness to market demands.

Long-term partnership opportunities with established manufacturers committed to international standards.

Real-World Applications of Ice Bath Chillers from Vietnam

Ice bath chillers manufactured in Vietnam are now widely used across multiple industries. Fitness centers and gyms use them to support athletic recovery routines. Spas rely on them to enhance wellness experiences. At the same time, rehabilitation clinics use these chillers to provide cold therapy for patients with muscle injuries or post-surgical inflammation. Thanks to their compact design, high energy efficiency, and customizable control systems, Vietnam-made chillers are also becoming popular among homeowners who build personal wellness spaces.

What makes these chillers even more appealing is their compatibility with various tub materials, including stainless steel, inflatable, acrylic, and wooden cold plunge tubs. Whether for commercial or residential use, these units are built to maintain low water temperatures consistently, even during intensive use. This versatility makes Vietnam an attractive destination for sourcing ice bath chillers for both small businesses and large-scale distributors.

Frequently Asked Questions

Are ice bath chillers made in Vietnam reliable?

Yes. Most Vietnam-based factories follow strict quality control protocols and hold ISO 9001 and CE certifications. Their chillers are tested for performance, safety, and durability before shipping.

Do Vietnam chiller manufacturers support OEM orders?

Absolutely. You can customize everything from voltage and size to the outer casing, branding, and control interfaces. OEM and ODM services are available for distributors and brand owners.

How long does it take to produce and ship a chiller from Vietnam?

Production generally takes 10 to 15 working days, and shipping varies depending on your destination. For most U.S. and EU orders, delivery is completed within 2 to 4 weeks.

To learn more about our high-quality ice bath chillers and explore our complete range—including economy, standard, high-end, and OEM-customized options—visit our Products Page.

Discover why sourcing from Vietnam offers your business the strategic advantage it needs to thrive in today’s competitive market.